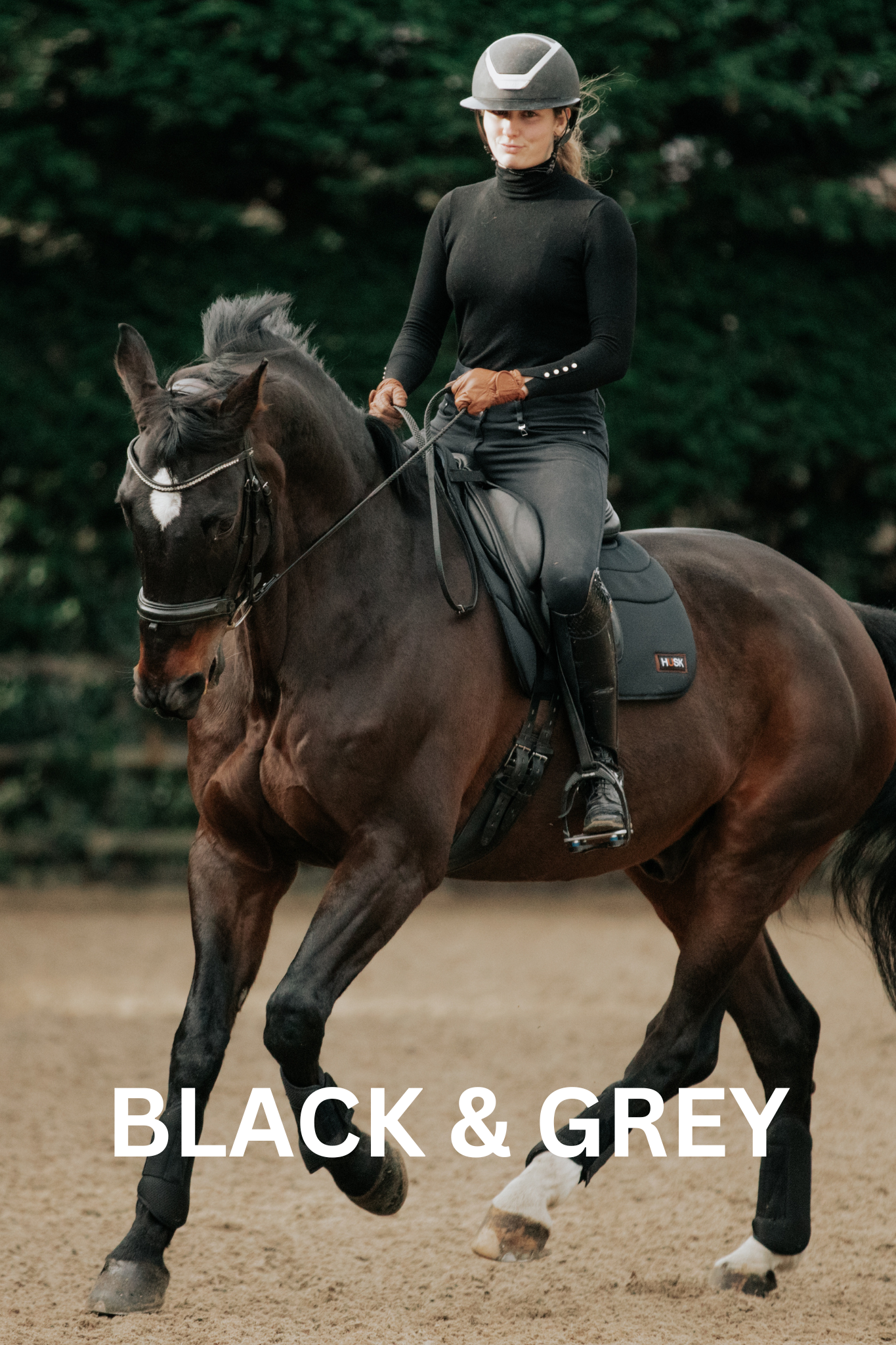

HUSK Air Boot Impact Tests

Do you know if your horse's leg protection has been tested for impact?

HUSK Air Boots are made with precision and the consistent desire to make

the BEST leg protection for horses in the world.

Here are the PROMISES that we make to horses

all over the world with our HUSK Air Boots:

- With that we source the highest quality fabrics, and we never swap them out for anything less

- We ensure that our fabrics are tested for durability, as well as qualities such as impact, compression, and of course breathability

- We consistently test our products and listen to customer feedback with the aim to improve our boots where we can

- Our designs are unique to us, we don't copy others as we seek to be AHEAD of the market with innovation, to consistently improve on what we have already, not go backwards

- We ensure HUSK leg protection is light, and minimises any discomfort or distraction to horses

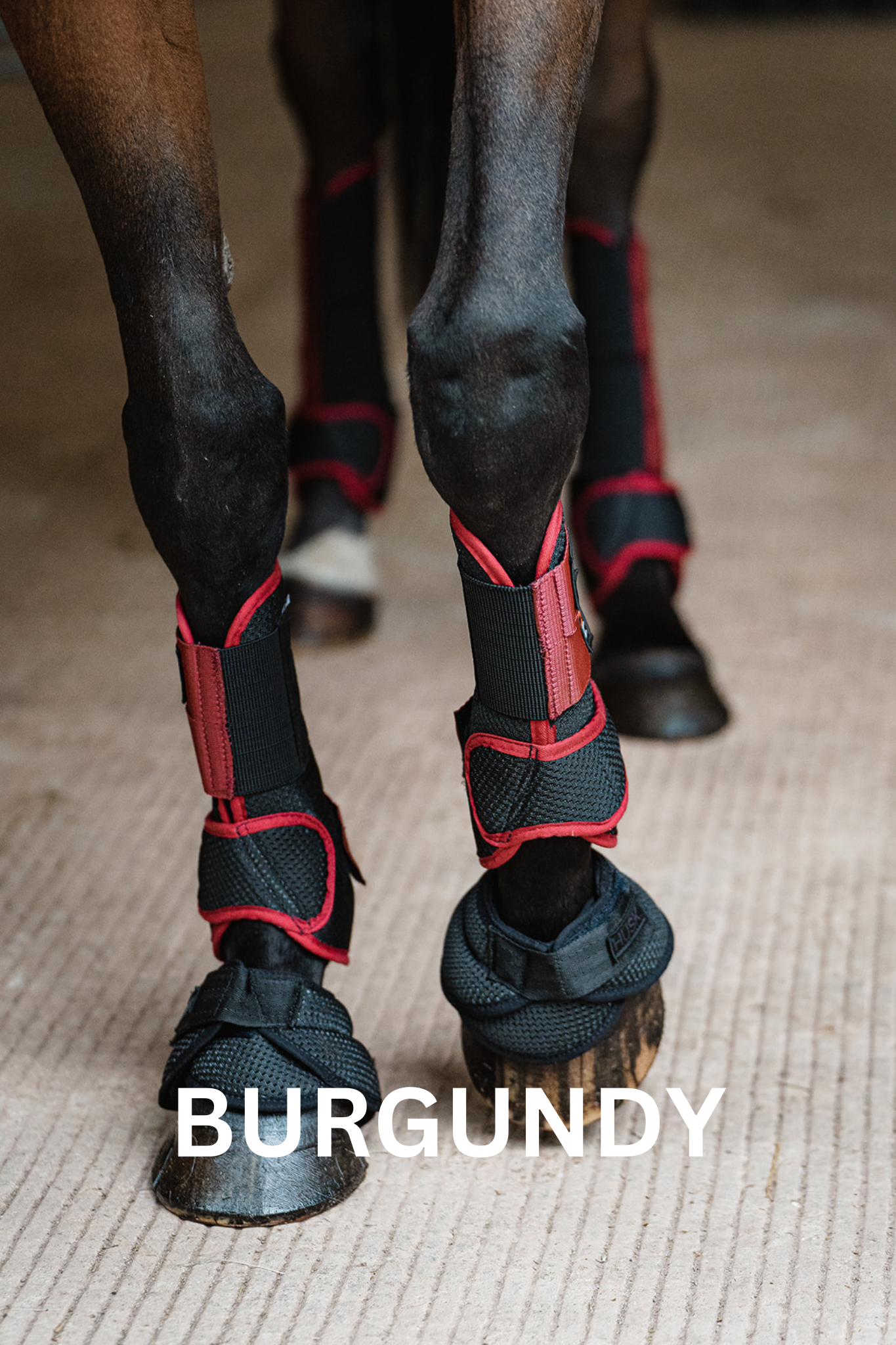

Here's HUSK's Fabric Compressional Tests:

We looked at how much compression was required to compress the fabric by 40% using an industry standard test BS EN ISO 3386-1. The compression required was 43.4 kPa.

HUSK's Warp and Weft Tests:

We use an industry standard test BS EN ISO 6330: 4A/50/A and the maximum the fabric can be mis-shaped is 5%

HUSK are proud to demonstrate these statistics for our fabrics that we use to embody our Air Boots are of high quality and tested to ensure consistency of the quality that we promote, and that we offer only the BEST to our horses.